Automatic Vertical 1100rpm Vegetable Oil Centrifuge Food Grade

Product Details:

| Place of Origin: | CHINA, JIANGSU |

| Brand Name: | HUADA |

| Certification: | GB/T19001-2016/ISO9001:2015 |

| Model Number: | PSB1200 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 set |

|---|---|

| Price: | USD17000/set |

| Packaging Details: | Standard with wooden pallet and poly film wrapping |

| Delivery Time: | 60 work days |

| Payment Terms: | T/T, L/C, Western Union |

| Supply Ability: | 100 sets per month |

|

Detail Information |

|||

| After-sales Service Provided: | Engineers Available To Service Machinery Overseas | Basket Diameter(mm): | 1200 |

|---|---|---|---|

| Discharge: | Bag Top Discharge | Max. Capacity(kg): | 340 |

| MOC: | Stainless Steel | Max. Speed(r/min): | 1100 |

| Rotating Speed Control: | Frequency Converter | Online Washing System: | Optional |

| High Light: | 1100rpm Vertical vegetable oil centrifuge,1100rpm automatic centrifuge machine,vegetable oil centrifuge Food Grade |

||

Product Description

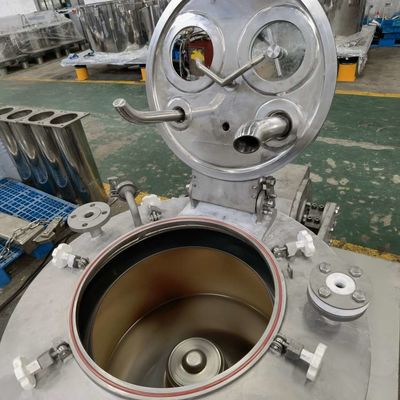

PSB Automatic Vertical PLC Control Food Grade Vegetable Oil Processing Convenient Separating Plant

The PSB/PBZ series are enclosed manual top discharge and filtration centrifuges designed in line with the GMP standards and environmental protection requirements, which can be used for separating a wide range of materials. This product is highly applicable to the separation of various suspensions and fibrous materials with high temperature, strong viscosity and small particle sizes (minimum size of 1μm). Characterized by high separation factor, simple structure and high performance, the PBZ300 and 450 products are commonly selected as testing machines by various research institutions.

![]()

Main Features

- In compliance with the GMP standards: enclosed structure designed to effectively avoid contamination of materials. Configured with CIP online cleaning system to realize all-around cleaning.

- Wide opening structure designed for easier discharging and replacement of the filter bag.

- Small floor covering area, easy maintenance, low failure rate and long service life.

- High separation factor designed for better separation effect.

- Light in structure, simple in operation, low in gravity center, small in vibration and stable in operation.

- Grains less prone to breakage, with a wide scope of application.

- Multiple safety protection configurations, variable frequency control to realize stepless regulation of speed.

- Platform base design lowers the center of gravity and requires minimum installation space. The platform base can be used for operation platform.

- Big hinged cover, feeding pipe, washing pipe, observation glass and light.

- Automatic CIP system cleans the internal surface of the case, the basket and liquid slot to meet the clean requirement in accordance with GMP standards.

- Wide range of applications. No damage to the particle shape.

- Inverter start-up, smooth starting, adjustable relative centrifugal force.

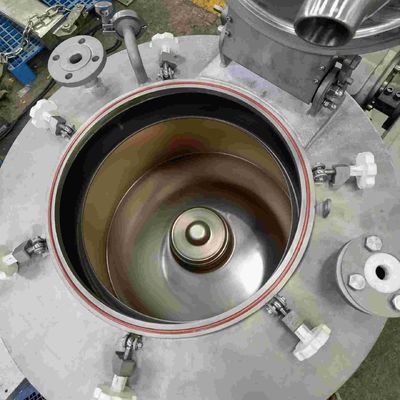

- Tightness structure with silicone rubber or fluoroelastomers seals. Nitrogen protection system (optional) is for anti-explosion applied to poisonous, flammable and explosive environment.

- Model PBZ centrifuge has applied direct shaft connected motor, which eliminates frictional dust from belt drive. In the meantime, the motor is installed at the bottom of the machine, which requires minimum installation space.

![]()

![]()

PSB lined with PE PSB lined with HL

![]()

![]()

PSB PBZ

Technical Parameters

| Items | Models |

| PSB1200 | |

| Basket Diameter(mm) | 1200 |

| Effective Basket Height(mm) | 550 |

| Basket Volume(L) | 270 |

| Max. Capacity(kg) | 340 |

| Max. Speed(r/min) | 1100 |

| Max. Separation Factor | 812 |

| Motor Power(kw) | 15 |

| Dimension(mm) | 2300*1550*1500 |

| Weight(kg) | 3000 |

PROCEDURE CONTROL

Huada has a professional quality management team, which implements each link related to users and products from contract review, technical design, material procurement, manufacturing process to after-sales service according to standard operating procedure, to effectively control the full process from design, purchasing, manufacturing to service.

Contract review

For individual requirements of customers, we make security risk evaluation specific to contract and technical agreement, to ensure that safety requirements. We confirm individual configuration and changes and propose quality plan and opinions.

Process control

Quality plan: For each order, at the time of design output, we put forward the quality plan of the production batch according to the customers’ individual requirements and internal quality control requirements and make clear information like material, configuration, individual changes, inspection requirements and special agreement.

The quality plan is the internal control document for purchase, manufacture, inspection and confirmation for this batch.

ERP process: Through process and permissions settings, we standardize the product realization process including design output, change, procurement, materials distribution, machining process, inspection and records, warehouse-in and warehouse-out.

For every process, whether purchasing, internal parts processing or assembly process, we have established strict quality control requirements. For welding, surface coating, main and key parts processing and general assembly, we have formulated detailed operation and inspection regulations to ensure effective control of each process.